Marine airbags are also known as inflatable ship launching airbags, roller bags, air lift bags, and salvage bags. Airbags range in size from 0.8 to 2.5m diameters, with lengths of 6.0m to 23.0m ‘effective length’. They are widely used in cargo boat launching and landing, lifting and moving sunken ships, and salvaging stranded boats. Marine airbags have the benefit of not only saving labor and time but also costs saving. They are flexible, portable, and dependable. Additionally, they are flexible, portable, and dependable. Therefore, marine airbags are very popular with shipyards, shipowners, and marine supplies companies now.

Features of Marine Airbags:

- High bearing capacity

- High resistance to knead ability

- Optimization of structural layout

- Durable anti-aging abilities and wear resistance

- Higher flexibility and shock absorption ability

Materials of Marine Airbags:

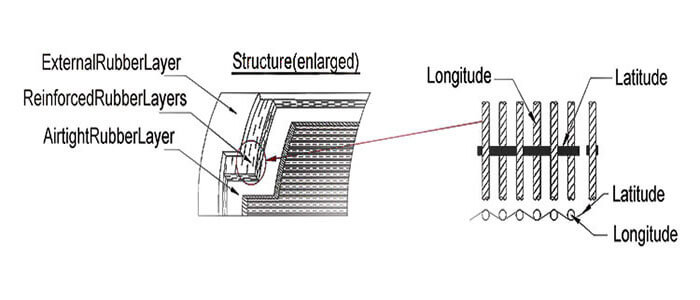

Structures of Marine Airbags:

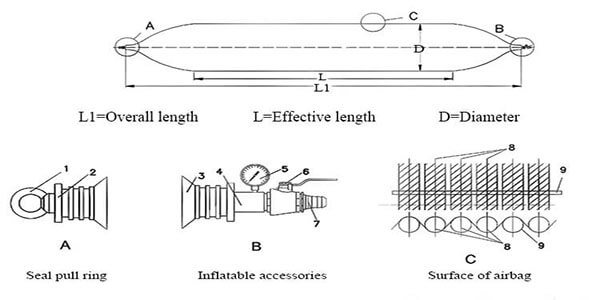

- Pull Ring

- End Hardware

- End Hardware

- Three-way Pipe

- Pressure Gauge

- Valve

- Hose Connector

- Radical Lines

- Latitude

Marine airbag consists of three parts: Airbag body: the main, cylindrical part of the air bag after being fully inflated with compressed air.

Airbag head: conical parts connecting the body and the mouths of the air bag.

Airbag mouths: either metal valves mounted on both ends of the air bag for inflating with air or a valve on one end and a metal lug on the other end used to haul the air.

| Diameter | Working Pressure | Working height | Bearing capacity per unit length | |

| KN/m | ton/m | |||

| D=1.0m | 0.20Mpa | 0.6m | 125.76 | 12.82 |

| 0.5m | 157.16 | 16.02 | ||

| D=1.2m | 0.17Mpa | 0.7m | 133.61 | 13.62 |

| 0.6m | 160.3 | 16.34 | ||

| D=1.5m | 0.13Mpa | 0.9m | 112.63 | 12.5 |

| 0.8m | 143.03 | 14.58 | ||

| 0.7m | 163.43 | 16.66 | ||

| D=1.8m | 0.11Mpa | 1.1m | 120.96 | 12.33 |

| 1.0m | 138.22 | 14.09 | ||

| 0.9m | 155.59 | 15.86 | ||

| 0.8m | 172.85 | 17.62 | ||

| 0.7m | 190.22 | 19.39 | ||

| D=2m | 0.10Mpa | 1.2m | 125.76 | 12.82 |

| 1.1m | 141.46 | 14.42 | ||

| 1.0m | 157.16 | 16.02 | ||

| 0.9m | 172.85 | 17.62 | ||

| 0.8m | 188.64 | 19.23 | ||

The length of ship launching airbag is specified by the customer when it is manufactured. Besides, we will choose a reasonable size for the customer, according to the information provided by the customer, such as the type of vessel, LOA of ship, vessel's actual launched weight.

Ship launching airbag overall winding structure uses cross whole intertwine technology, which make its overall structure more reasonable, texture clear.

Overall Winding Vulcanization

Overall Winding Vulcanization

Ship launching airbag is widely used in cargo boat launching and landing, lifting and moving sunken ships, installation of underwater buoyancy aid, and salvaging stranded boats.