Marine rubber airbag is an innovative and safe technique to launch ships in the water, which is made of reinforced rubber layers and has a high load capacity. They are usually cylindrical in shape with hemispherical heads at both ends. Besides, marine rubber airbag is not only used for ships, floating docks and caisson launching but they are also cutting edge for ship landing, heavy transport, marine salvage, etc. It is a versatile tool for many marine applications. Additionally, they are flexible, portable, and dependable. Therefore, Airbags are very popular with shipyards, shipowners, and marine supplies companies now.

Advantages:

-

- The ship launching airbag overcomes the shortcomings of the fixed launching track, which limits the productive capability of the small and medium-sized shipyards.

- Using the ship launching airbag becomes a flexible launching technology. It has the advantage of saving time and labor.

- The airbag has the characters of flexibility, reliability, and safety in ship launching operation, and also economic.

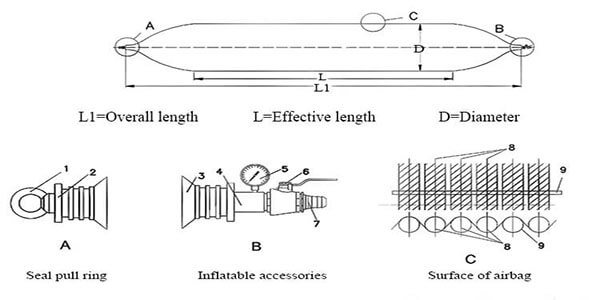

Structures of Marine Airbags:

- Pull Ring

- End Hardware

- End Hardware

- Three-way Pipe

- Pressure Gauge

- Valve

- Hose Connector

- Radical Lines

- Latitude

The ship launching airbag consists of three parts: Airbag body: the main, cylindrical part of the airbag after being fully inflated with compressed air.

Airbag heads: conical parts connecting the body and the mouths of the airbag.

Airbag mouths: either metal valves mounted on both ends of the airbag for inflating with air or a valve on one end and a metal lug on the other end used to haul the air.

Materials of Marine Airbags:

| Diameter | Working Pressure | Working height | Bearing capacity per unit length | |

| KN/m | ton/m | |||

| D=1.0m | 0.20Mpa | 0.6m | 125.76 | 12.82 |

| 0.5m | 157.16 | 16.02 | ||

| D=1.2m | 0.17Mpa | 0.7m | 133.61 | 13.62 |

| 0.6m | 160.3 | 16.34 | ||

| D=1.5m | 0.13Mpa | 0.9m | 112.63 | 12.5 |

| 0.8m | 143.03 | 14.58 | ||

| 0.7m | 163.43 | 16.66 | ||

| D=1.8m | 0.11Mpa | 1.1m | 120.96 | 12.33 |

| 1.0m | 138.22 | 14.09 | ||

| 0.9m | 155.59 | 15.86 | ||

| 0.8m | 172.85 | 17.62 | ||

| 0.7m | 190.22 | 19.39 | ||

| D=2m | 0.10Mpa | 1.2m | 125.76 | 12.82 |

| 1.1m | 141.46 | 14.42 | ||

| 1.0m | 157.16 | 16.02 | ||

| 0.9m | 172.85 | 17.62 | ||

| 0.8m | 188.64 | 19.23 | ||

The length of ship launching airbag is specified by the customer when it is manufactured. Besides, we will choose a reasonable size for the customer, according to the information provided by the customer, such as the type of vessel, LOA of ship, vessel's actual launched weight.

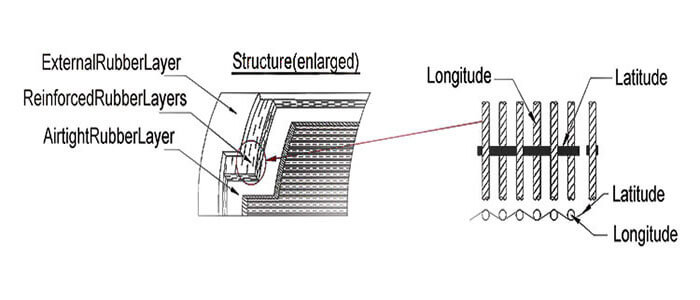

Ship launching airbag overall winding structure uses cross whole intertwine technology, which make its overall structure more reasonable, texture clear.

Overall Winding Vulcanization

Overall Winding Vulcanization

Ship launching airbag is widely used in cargo boat launching and landing, lifting and moving sunken ships, installation of underwater buoyancy aid, and salvaging stranded boats.